Welcome To S&S Precision, Inc.

Founded in 1979 as a quality supplier of precision die tooling and mold cavity parts, S&S Precision Inc. prides itself in its ability to deliver products meeting or exceeding its customers’ exacting requirements.

Our main focus is blank and draw tools and mold cavity tools. Secondary capabilities include small, compound dies and general machining and grinding. Wire EDM services are also available.

Products We Offer

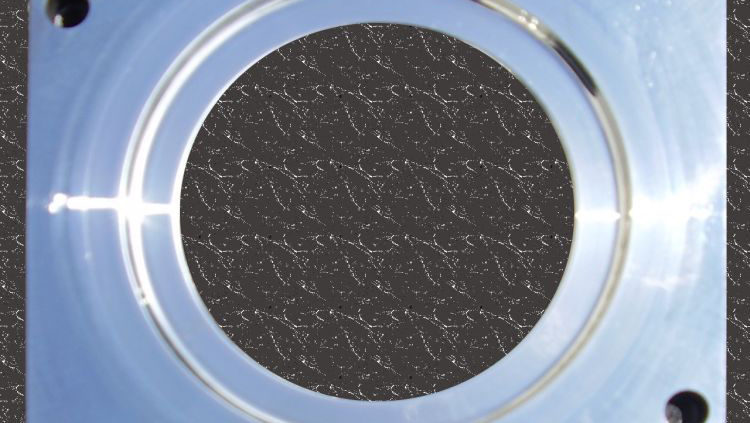

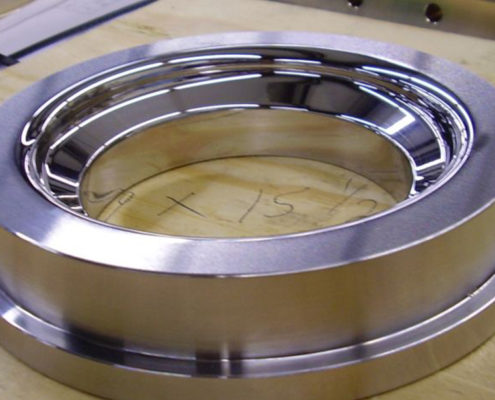

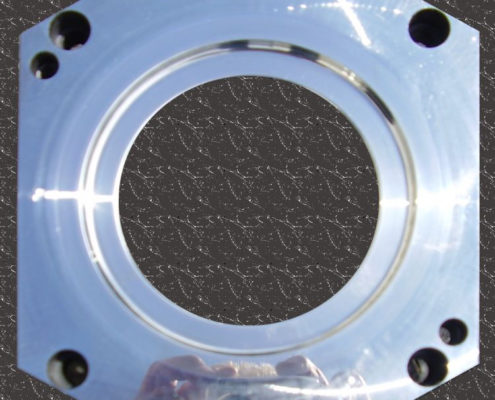

S&S Precision produces numerous high-quality parts for our customers. Below are samples of just a few of our recent projects.

- Solid Carbide

- Carbide Inserts

- Stainless Steel

- Aluminum

- Specialty coppers and bronze

- All types of hardened tool steel

Available Equipment

Gallery

Contact Us By Phone

(615) 384-6286

Send Us A Fax

(615) 384-2342

Send Us An Email

info@sandsprecision.net